Sheep Hoof Trimming Tools: How to Trim 50 Ewes and Still Feel Your Wrists

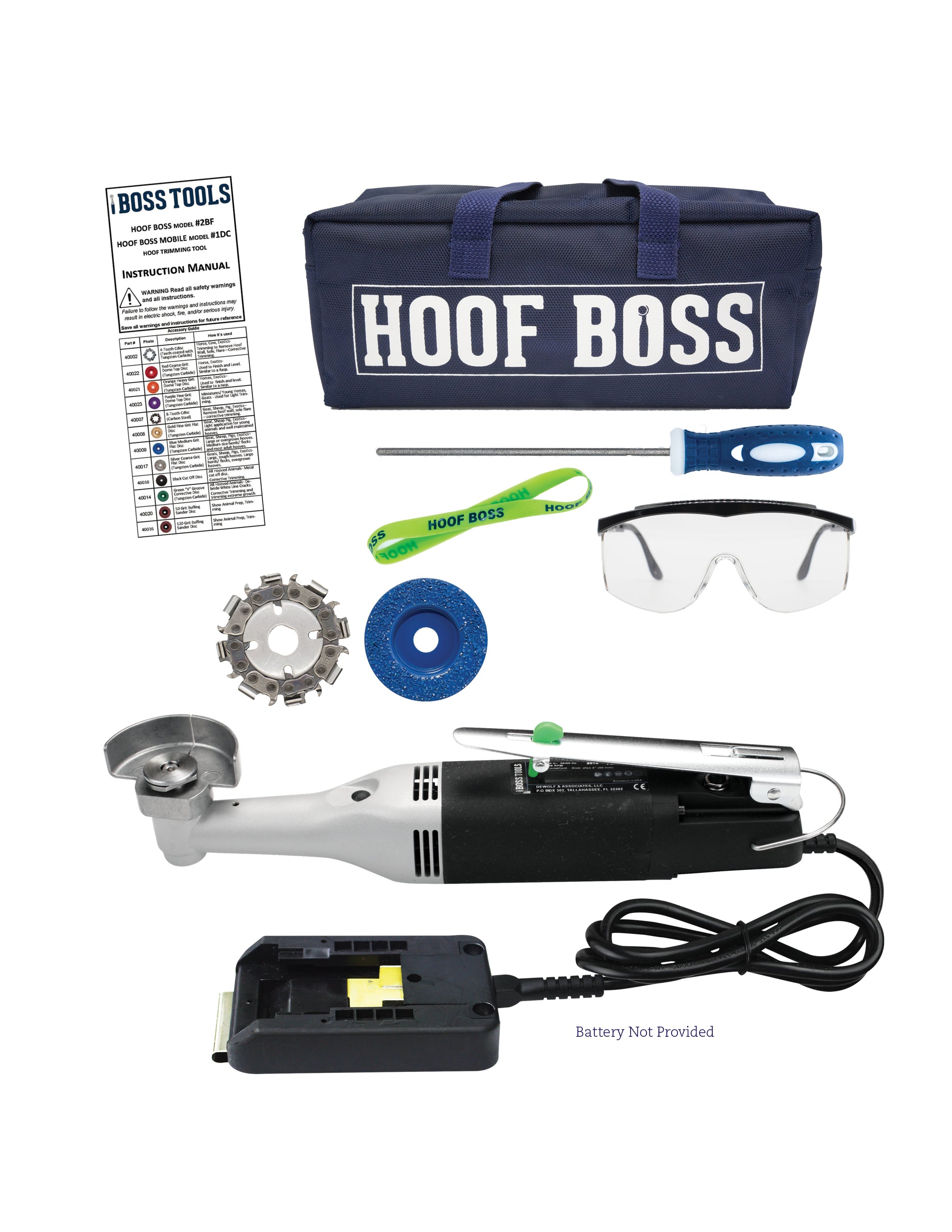

Soft pasture lets horn grow faster than it wears; left unchecked, it curls, packs with mud, and invites foot rot. A purpose-built trim station—anchored by the Hoof Boss Electric Sheep Trimmer—keeps sessions brisk, cuts cleaner, and spares both flock and crew.

Why the Right Tools Matter

-

Faster sessions that finish an ewe in about two minutes

-

Smooth cuts that seal quickly and resist infection

-

Lower hand and back fatigue—even on big barn days

-

Fewer slips or over-trims because every edge is sharp and task-specific

Setting Up an Efficient Trim Bay

-

Secure the stand and lighting. Place a sturdy sheep stand on level concrete; aim LED strips at hoof height so bruises and white-line cracks can’t hide.

-

Position the Hoof Boss within easy reach. Hang it on a retractable reel; quick-swap discs—60 grit for excess wall, 120 for leveling, 240 for a final polish—stay in labeled bins beside the stand.

-

Keep hand tools close, not cluttered. A magnetic rail holds ratcheting nippers for spot reductions and loop knives for small abscess tracks; a diamond-coated rasp rests underneath for fidgety ewes that need a final blend.

-

Roll in an antiseptic cart. Stock chlorhexidine spray, blood-stop powder, gauze, and towels so every nick is disinfected before the ewe hops off.

-

Add dust control and hygiene. A low-speed fan pulls horn dust away from lungs; pressure-wash the bay after every trim day, oil the trimmer spindle lightly, and wire-brush disc faces to keep grit biting.

A trim station built on these five workflow checkpoints turns hoof day from a marathon into a smooth routine. With the Hoof Boss Electric Sheep Trimmer doing the heavy lifting and support tools staged where you need them, the flock stays light on its feet—and you stay light on ibuprofen.

Shop the Hoof Boss Sheep Hoof-Care Collection and upgrade from makeshift kits to a trim bay that works as hard as your herd.